PSX: Positive Seal

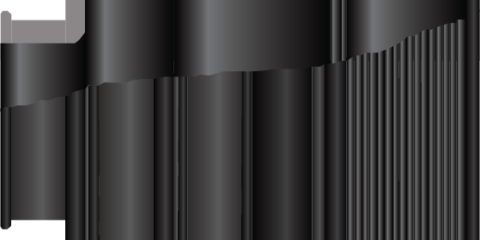

The PSX: Positive Seal is a high-performance flexible pipe-to-manhole connector that offers easy installation and long-term performance in one convenient product.

- Used in stormwater and wastewater applications

- Meets or exceeds ASTM C 923, ASTM C 1244, ASTM C 1478, ASTM F 2510

What It Is

The PSX: Positive Seal is a high-performance flexible pipe-to-manhole connector that offers easy installation and long-term performance in one convenient product.

Literature

Full Literature

How It Works

- The connector fits into a cast or cored hole.

- A power sleeve made from tempered series 304 stainless steel expands with a calibrated hydraulic installation tool.

- Take-up clamps made from series 304 stainless steel with quick adjusting screws secure the connector to the pipe.

Why It's Better

- Safely install from outside of the manhole preventing falls from crawling down into structures.

- All stainless-steel components with no welds or rivets creating a stronger product.

- Precision molding provides accurate compensation for hole size variations.

- Contractor can save time and money by backfilling immediately.

Meets or Exceeds

- ASTM C 923 – Standard Specification for Resilient Connectors Between Reinforced Concrete Manhole Structures, Pipes, and Laterals

- ASTM C 1244 Standard Test Method for Concrete Sewer Manholes by the Negative Air Pressure (Vacuum) Test

- ASTM C 1478 – Standard Specification for Storm Drain Resilient Connectors Between Reinforced Concrete Storm Sewer Structures, Pipes, and Laterals

- ASTM F 2510 Standard Specification for Resilient Connectors Between Reinforced Concrete Manhole Structures and Corrugated High Density Polyethylene Drainage Pipes

Where To Use

- Manholes

- Wet wells

- Square pump and lift stations

- Stormwater structures

- On-site treatment structures

- Junction chambers

- Grease interceptors

A watertight flexible pipe-to-manhole connector shall be employed in the connection of the sanitary sewer and/or stormwater pipe to precast manholes or other structures.

The connector shall be PSX: POSITIVE SEAL as manufactured by Press-Seal Corporation, Fort Wayne, Indiana, or approved equal.

The connector assembly shall be the sole element relied on to assure a flexible watertight seal of the pipe to the structure. The connector shall consist of a rubber gasket, an internal expansion sleeve, and one or more external compression take-up clamps. Approved materials for the connector shall be virgin rubber and Series 300 non-magnetic stainless steel. No plastic components shall be permitted.

The rubber gasket element shall be constructed solely of synthetic or natural rubber, shall meet/exceed the requirements of ASTM C 923, and shall have a minimum tensile strength of 1600 PSI. Minimum thickness of the cross-section shall be 0.275 inches (7 mm).

The internal expansion sleeve components shall be made of Series 300 non-magnetic stainless steel and shall utilize no welds in their construction.

Installation shall be performed using a calibrated installation tool available from the connector manufacturer. Installation of the sleeve shall require no retightening after the initial installation.

The external compression take-up clamp(s) shall be constructed of Series 300 non-magnetic stainless steel and shall utilize no welds in its constructions. The clamp(s) shall be installed by torqueing the adjusting screw using a torque-setting wrench available from the connector manufacturer.

Selection of the proper size connector for the manhole and pipe requirement, and installation thereof, shall be in strict conformance with the recommendations of the connector manufacturer. Any dead end pipe stubs installed in connectors shall be restrained from movement per ASTM C 923.

The finished connection shall provide sealing to 13 psi (minimum), and shall accommodate deflection of pipe to 7 degrees (minimum) without loss of seal.

Vacuum testing shall be conducted in strict conformance with ASTM C 1244 prior to backfill. Other testing shall be conducted in strict conformance with the requirements of the connector manufacturer.

- Inspect hole. Wall surface must be CLEAN and SMOOTH. Fill all voids with

non-shrink cementations patching compound and allow to dry. - Place gasket into porthole with holes in stainless steel power sleeve at the 6 o’clock position. Gasket should rest 1/2” to 1” from the inside of the hole.

- Place hydraulic tool inside gasket and open slightly by closing valve and pumping the handle on hydraulic unit. Align and insert studs of tool in

holes of power sleeve. (see illustration A) - Once studs are inserted in power sleeve, pump hydraulic unit until gasket stays positioned in the hole without any hand assistance. Gasket

must be aligned square in the hole at this point. Make any necessary

adjustments in sleeve ends to ensure that they are aligned on top of

each other. - Pump the hydraulic unit to start expanding power sleeve. (see illustration B)

- Continue pumping the hydraulic unit while watching sleeve ends to

make sure they stay aligned on top of each other. - Once the sleeve ends snap into place face-to-face, check the gauge to

make sure minimum pressure (see above) has been achieved. - Relax the power sleeve slightly by releasing valve on hydraulic pump.

This will interlock the ends of the power sleeve to ensure a positive seal.