4G Nitrile Pipe Gaskets

Nitrile 4G Gaskets are high-performance gaskets for concrete pipe which combine watertight sealing performance with the ability to resist common underground contaminants.

Document Downloads

Download Product Literature Download Box Culvert Literature

The Type 4G Nitrile gaskets were developed to specifically meet the needs of contemporary concrete pipe joint designs, while providing the ability to resist common underground contaminants.

How It Works

- The gasket is stretched over the spigot.

- The gasket is equalized around the entire circumference of the spigot.

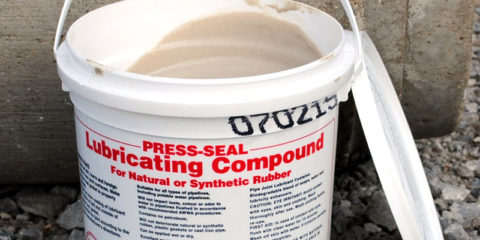

- Bell joint is covered liberally with lubricant.

- Bell and spigot are homed creating a watertight seal.

Why It's Better

- Optimized profile designs for a variety of joint configurations.

- Accurate profile designs covering a variety of underground contaminant applications.

- Simple installation methods.

Where To Use

- Convenience Stores

- Petroleum Storage Terminals

- Pipeline Terminals

- Refineries

- Auto Dealerships

- Car/Truck Washes

- Airport Ramps or Deicing Facilities

- Manholes

- Wet wells

- Pumps and lift stations

Please Note

Nitrile pipe gaskets are non-stock items and take 4-8 weeks lead time for production.

In addition to resistance to common hydrocarbons, Nitrile 4G also offers improved resistance to mixed contaminated chemistries. This is especially important where contaminants and their concentrations cannot be accurately predicted or determined. This can result in interactions among the contaminants which are difficult to anticipate and define.

| TEST REQUIREMENTS and RESULTS for NITRILE 4G GASKETS as in ASTM C1619 Class D, and ASTM C 443-04 and CSA 257.3-03 for Oil-Resistant Gaskets |

|||

|---|---|---|---|

| Test | ASTM Test Method | Test Requirements | Typical Result |

| TENSILE STRENGTH | D 412 | 1200 PSI, MIN. | 1403 PSI |

| ELONGATION AT BREAK | D 412 | 350%, MIN. | 563% |

| HARDNESS | D 2240 (SHORE A DUROMETER) | ±5 FROM THE MANUFACTURER’S SPECIFIED HARDNESS | <2 |

| ACCELERATED OVEN-AGING | D 573, 70± 1ºC FOR 7 DAYS | DECREASE OF 15%, MAX. OF ORIGINAL TENSILE STRENGTH, DECREASE OF 20%, MAX. OF ELONGATION | -3% TENSILE CHANGE, -10% ELONGATION CHANGE |

| COMPRESSION TEST | D 395, METHOD B, AT 70ºC FOR 22 HRS | DECREASE OF 25%, MAX. OF ORIGINAL DEFLECTION | 10% |

| WATER ABSORPTION | D 471 IMMERSE 0.75 BY 2-IN. SPECIMEN IN DISTILLED WATER AT 70ºC FOR 48 hrs | INCREASE OF 10%, MAX. OR ORIGINAL BY WEIGHT | 2.70% |

| OZONE RESISTANCE | D 1171 | RATING 0 | PASS |

| LOW-TEMP, BRITTLE POINT | D 746 | NO FRACTURE AT -40ºC | PASS |

| OIL RESISTANCE D 471; ASTM IRM 9 | D 471; ASTM IRM 903 AT 100ºC FOR 70HRS | 80% MAX VOL. CHANGE | -1.9% |

An oil-resistant watertight rubber gasket shall be employed in the connections of concrete pipe for sanitary, stormwater, drainage, or other applications where contaminants are known or suspected.

The gasket shall be NITRILE 4G as manufactured by Press-Seal Corporation, Fort Wayne, Indiana, or approved equal.

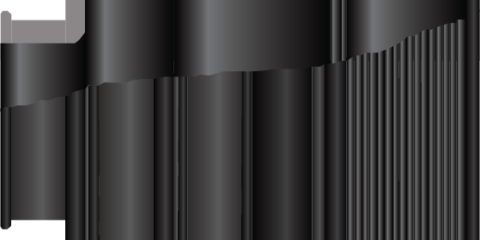

The gasket shall be the sole element relied on to assure a flexible watertight seal between pipe connections. The gasket shall consist of a single wedge-shaped rubber element. The rubber compound used shall consist of synthetic nitrile butadiene rubber polymer and shall conform with the sealing and oil resistance requirements of ASTM C1619, Class D, ASTM C 443-04 for Oil-Resistant Gaskets, and CSA 257.3-03 for Oil-Resistant Gaskets.

Each gasket shall be individually identified with continuous blue or green stripe toward the leading edge of the gasket. This stripe shall be used to positively identify that the gasket is NITRILE 4G and to confirm its proper orientation on the spigot of the pipe.

Selection of the proper size gasket for the pipe requirement, and installation thereof, shall be in strict conformance with the recommendations of the gasket manufacturer. Any testing also shall be conducted in strict conformance with the requirements of the gasket manufacturer.

Due to inherent properties of Nitrile gaskets, special considerations are noted:

- Nitrile gaskets are non-stock items, and they will require 4-8 weeks lead time for production and testing.

- Nitrile gaskets are higher durometer (harder), increasing pipe insertion forces. This hardness increases rapidly at lower temperatures, requiring special care in low-temperature installations (< 40F/4C).

- Nitrile rubber may occasionally have slight internal porosity. This is not a defect as long as the material meets all other specification requirements.

- Required splice testing strain may result in occasional splice breakage when the gasket is installed on the pipe. It is recommended that an additional quantity of gaskets (5 -10%) be ordered and supplied to compensate. In any event, Press-Seal will not be responsible for any consequent delays or damages related to this.

- Nitrile rubber hardens rapidly with age. Gaskets older than 12 months should be retested before use to ensure their continued suitability.

| NITRILE 4G PROFILE | GASKET SPACE |

|---|---|

| 158-4G | 0.326 (8.3 mm) |

| 210-4G | 0.446 (11.3 mm) |

| 288-4G | 0.500 (12.7 mm) |