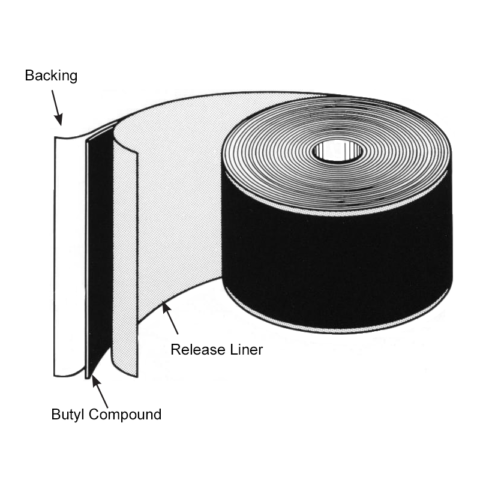

EZ WRAP – EPDM Backing

EZ-Wrap EPDM backing is a waterproofing membrane butyl adhesive tape designed to provide high strength adhesion on properly primed concrete surfaces and concrete structure joints.

Document Downloads

How It Works

- Exterior surface is cleaned and free of debris.

- EZ-Stik #4 primer or adhesive is applied

if needed - Wrap is cut to length prior to applying to joint.

- Release paper is removed and wrap is

applied to structure.

Why It's Better

- EPDM backing is resistant to direct sunlight that can damage rubber products.

- Coated release paper for easy installation.

- Better all-weather performance.

- High quality butyl rubber base.

- Adhesion to a variety of surfaces such as concrete, steel or even glass.

Where To Use

- Sanitary Manhole Joints

- Grade ring joints

- Stormwater Manhole Joints

- Irrigation and Drainage Systems

- Box Culverts

- Elliptical/Arch Pipe

- Architectural Foundations

- Underground Utility Vaults

- Stormwater Treatment & Inlet Structures

- On-Site Treatment Tanks

- Grease Interceptors

- Wet Wells

- Concrete bridge spans

- Applications that will leave wrap directly

exposed to sunlight

Meets or Exceeds

EZ-WRAP EPDM BACKING BUTYL JOINT WRAP meets or exceeds all requirements of the following Standards, Specifications and/or Test Methods:

- ASTM C 877 (Type III) – Standard Specification for External Sealing Bands for Concrete Pipe, Manholes, and Precast Box Sections

“Caution“

Keep both products away from heat, sparks or open flame. Use only with adequate ventilation. Avoid breathing vapors. Refer to MSDS for additional information.

Storage and Application Notes

EZ-PRIMER #4: Store and apply at temperatures from 32℉ (0 C) to 110 F (43 C). Shelf life of 12 months when stored in unopened original container. After opening, keep container covered when not in use.

EZ-WRAP: Store and apply at temperatures from 32℉ (0 C) to 110 F (43 C).

The joints and/or joining surfaces of the structures shall be sealed with a butyl-rubber-based tape. The material shall be EZ WRAP

rubber as supplied by PRESS-SEAL CORPORATION, Fort Wayne, Indiana, or approved equal. The butyl component of the tape shall consist of 50% (min.) hydrocarbon content (butyl rubber), shall contain 2% or less volatile matter, and shall be .074” (1.9 mm) thick. The backing component shall be EPDM rubber, and shall be .045” (1.1 mm) thick. A release paper may be utilized.

For manholes, the tape width shall be 6” (150 mm) wide. The tape shall be overlapped at least twice its width. The tape shall not be stretched during application. Primer and/or adhesive as recommended by the tape supplier shall be employed for adverse, critical, or other applications.

Testing of joints and compliance with construction requirements shall be conducted in strict conformance with the requirements of the sealant supplier.

Clean the exterior surfaces of the joint area. Make sure that the cleaned area is at least 2” wider than the width of the EZ-WRAP used and that the cleaned area is centered on the joint. The concrete must be dry before applying wrap or primer. Primer is most important when installing in cold temperatures.

-

- Stir primer thoroughly before application to ensure rubber solids are equally dispensed throughout the solution. Using a paint brush or roller apply a thin even coat of EZ-STIK #4 PRIMER all the way around the joint. Prime the area at least 2” wider than the width of the EZ-WRAP used.

- Allow the solvents dispense from the primed surface (10-30 minutes depending on temperature), so that a clean, smooth surface is ready for installation of the EZ-WRAP.

- Cut the EZ-Wrap to the correct length prior to applying it to the joint. The below table will give you an idea of the most common lengths.

| 48” ID X 5” wall | 16 feet |

| 60” ID X 6” wall | 20 feet |

| 72” ID X 7” wall | 24 feet |

- The butyl sealant side of EZ-WRAP is protected by release paper. Apply the EZ-WRAP to the structure, taking care to centering it so both sides of the joint are equally covered; remove the release paper as you apply the EZ-WRAP. Press the EZ-WRAP down firmly and evenly as you cover the joint area. A rubber roller may be used to assist in applying even pressure.

- Complete the seal by overlapping the EZ-WRAP 6 to 9 inches .Apply #4 EZ STIK Primer to the section of EZ-Wrap attached to the manhole that will be covered by the overlap; let the solvents dispense from the #4 EZ STIK Primer; press the overlapped end firmly against the installed EZ-WRAP.

Never apply EZ-WRAP to wet #4 EZ STIK Primer