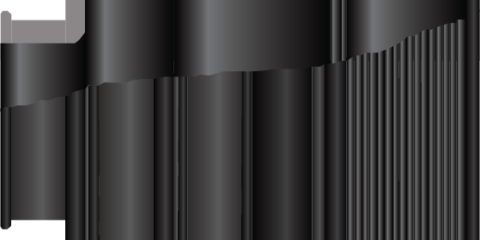

Nylon Rail Inserts

Our Nylon Rail Inserts provide a unique solution for rail maintenance and track engineers. The design and fabrication of the inserts reduces spalling and surface cracking. Applications include:

- Direct fixation rail pads

- Third rail brackets (electrical isolation anchor)

- Restraining rail brackets

- Anchor guard-rail

- Concrete tie inserts for turnouts

The INSULGARD railroad inserts can be used in precast or core-drilled applications. They can also help protect against stray current traveling down anchor bolts into rebar, underground utilities, and adjacent metal structures. The INSULGARD polymer material provides excellent electrical insulation properties and easily passes all IEC and ASTM electrical isolation test requirements.

Each load cone on the INSULGARD NS78 insert transfers upward tensile force out into the concrete at a 35 degree angle. This provides exceptionally high pullout values by widening the concrete spall zone.

STRAY CURRENT PROTECTION

For maintenance-of-way personnel engaged in repair and/or routine preventive maintenance, stray current protection is one of their top concerns. Typically stray-current occurs on rail spikes and fixtures to secure the rail to the ties. As materials in rail ties have advanced in their technology, state-of-the-art track design is now utilizing fasteners such as the railroad inserts to insulate and protect the materials from this stray current.

- No galvanic corrosion of fastening system

- Excellent impact resistance

- Broad spectrum chemical resistance

- Excellent long-term tensile strength

- Superior freeze-thaw characteristics

- Superior heat and weathering resistance

APPLICATIONS INCLUDE

Our railroad inserts can be utilized in a variety of track types including freight and transit in conjunction with our Corefast 3000 coring machine. Some of the applications include:

- Direct fixation plates

- Third rail brackets (electrical isolation anchor)

- Restraining rail brackets

- Anchor guard-rail

- Concrete tie inserts for turnouts

- Cast-in place slab track anchoring

- Chemical loading areas

- Segmental tunnel concrete ring inserts

MATERIALS INCLUDED

Although it’s more common to think of protection of stray current using glass-filled nylon inserts, we do provide railroad inserts in a variety of materials for specific project specifications or requirements. The materials we can provide are:

- Glass-filled nylon (very common usage)

- A325 Steel

- Weathering steel

- Stainless steel

- Ductile iron

And as always, our in-house dedicated engineering staff can design inserts to your specifications. If you need further information, contact our territory manager Gary Jones for more details or questions.