O-Ring Pipe Gasket

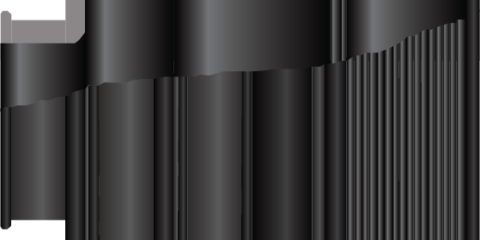

Press-Seal O-Ring concrete pipe gasket for concrete pipe utilizing a confined groove. The straightforward design fits perfectly with the necessary joint for a perfect fit every time.

What It Is

Press-Seal O-Ring concrete pipe gasket for concrete pipe utilizing a confined groove. The straightforward design fits perfectly with the necessary joint for a perfect fit every time.

Literature

Full Literature

How It Works

- Bell joint is covered liberally with lubricant.

- The gasket is covered liberally with lubricant.

- The gasket is stretched and placed into the groove .

- The gasket is equalized around entire circumference of spigot.

- Bell and spigot are honed creating a watertight seal.

Why It's Better

- Accurate diameter’s for a wide variety of joint configurations.

- Simplicity of design eliminates installing gasket in wrong direction or placement.

- Wide range of compounds that can be applied in multiple applications.

Meets or Exceeds

- ASTM C 1619 Standard Specification for Elastomeric Seals for Joining Concrete Structures

- ASTM C 443 Standard Specification for Joints for Concrete Pipe and Manholes, Using Rubber Gaskets

- ASTM C 361 Standard Specification for Reinforced Concrete Low-Head Pressure Pipe

- CSA A 257.3 Gaskets for Concrete Pipe

Where To Use

- Manholes

- Wet wells

- Square pump and lift stations

- Stormwater structures

- On-site treatment structures

- Junction chambers

- Grease interceptors

- Reinforced concrete pipes

Please Note

Press-Seal can provide pipe gaskets in oil resistant neoprene or NSF materials. Please contact us or your territory manager for more information.

- The pipe should be handled with extreme caution to avoid chipping of the spigots or bell grooves.

- Carefully clean all dirt and foreign objects from the jointing surface of the bell or groove end of pipe. Carefully clean spigot or tongue end of pipe,

including the gasket recess. Improperly prepared bell and spigot

surfaces may prevent homing of the pipe or keep the gasket from sealing - Lubricate bell joint surface liberally, cover entire inside surface, including the entrance slope using Press-Seal pipe gasket lubricant. A bell and gasket not lubricated or improperly lubricated may cause the gasket to roll and leak or possibly damage the bell.

- Lubricate the gasket thoroughly before it is placed into the groove on the spigot. Excessive force will be needed to push the pipe home if the gasket is not well lubricated.

- Install the gasket carefully in the o-ring groove. Equalize the rubber gasket stretch by running a smooth, round object (inserted between gasket and spigot) around the entire circumference several times. Unequal stretch could create bunching of the gasket and may cause leaks in the joint or crack the bell.

- Align the bell and spigot to be joined. Before homing the joint, check that the gasket is in contact with the bell end entrance taper around the entire circumference.Improper alignment can dislodge gasket causing leaks or possibly breaking the bell