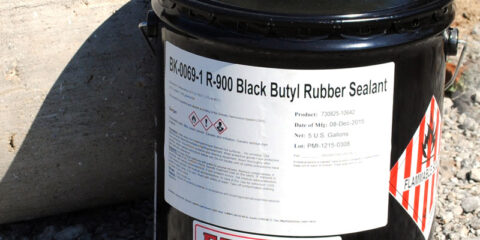

PRO-STIK Butyl Sealant

Pro-Stik is an all weather butyl rubber sealant for concrete joints. Butyl sealants are far superior to mastic made from oil or asphalt because they are rubber based.

What It Is

Pro-Stik is an all weather butyl rubber sealant for concrete joints. Butyl sealants are far superior to mastic made from oil or asphalt because they are rubber based.

They exhibit physical properties such as superior rebound, compression set, low temperature and high temperature flows that are required for long term sealing performance and ease of installation.

Butyl sealant offers the end user maximum sealing performance and ease of use with no oily mess and are environmentally friendly. Pro-Stik is a high quality butyl rubber joint sealant. Pro-Stik is one of two butyl rubber based sealants we offer for sealing concrete structures. The other is EZ STIK. Butyl sealants are rubber based, and exhibit sealing properties superior to bitumen based products.

Literature

Installation Instructions

Box Culvert Product Literature

How It Works

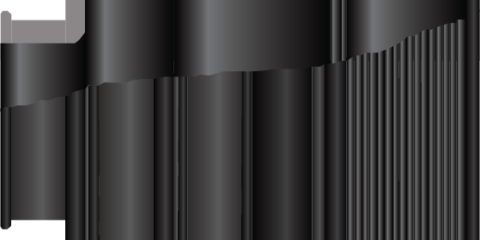

- Sealant is applied as a continuous ring around entire joint.

- The excess sealant is then cut to length to create a butt joint.

- Ends of butt joint are kneaded together.

- Protective release paper is removed from the sealant ring.

Why It's Better

- Better all-weather performance.

- Low moisture vapor transmission rate (MVTR).

- Excellent adhesion to a wide-range of surfaces.

- Long service life.

- A variety of shapes and sizes to fit almost any application.

- Allow for joint movement while maintaining sealing properties.

Meets or Exceeds

- ASTM C 990 – Standard Specification for Joints for Concrete Pipe, Manholes, and Precast Box Sections Using Preformed Flexible Joint Sealants; Section 6.2 Butyl Rubber Sealants

- AASHTO M 198 – Joints for Circular Concrete Sewer and Culvert Pipe Using Flexible Watertight Gaskets

- ASTM C 972 – 00(2011) – Standard Test Method for Compression-Recovery of Tape Sealant

- ASTM C 765 – 97(2015) – Standard Test Method for Low-Temperature Flexibility of Preformed Tape Sealants

Where To Use

- Sanitary Manhole Joints

- Stormwater Manhole Joints

- Irrigation and Drainage Systems

- Box Culverts

- Elliptical/Arch Pipe

- Architectural Foundations

- Underground Utility Vaults

- Stormwater Treatment & Inlet Structures

- On-Site Treatment Tanks

- Grease Interceptors

- Wet Wells

The joints and/or joint surfaces of the structures shall be sealed with a butyl-rubber-based preformed flexible sealant conforming to ASTM C990, paragraph 6.2. The material shall be PRO-STIK or EZ-STIK as supplied by PRESS-SEAL CORPORATION, Fort Wayne, Indiana, or approved equal. The butyl material shall consists of 50% (min.) butyl rubber and shall contain 2% or less volatile matter.

For preformed joint sealants, the sealant shall be sized such that the joint is filled to 50% (min.) of its annular volume when fully assembled, and the sealant shall have the ends kneaded together at the overlap. Primer and/or adhesive as recommended by the sealant supplier shall be employed for adverse, critical, or other applications.

Testing of joints and compliance with construction requirements shall be conducted in strict conformance with the requirements of the sealant supplier.

- Dry joint surface if wet.(Joint surface must be dry.)

- Clean all dirt, sand, mud, etc. from joint

- Remove roll from carton.(Keep away from dirt, etc.)

- Place exposed surface down/ place against vertical surface/press against concrete

- Apply sealant in continuous ring around the joint (DO NOT STRETCH!)

- To complete sealant ring cut off excess sealant with knife or sharp object

- Cut sealant so that when cut, the ends form a butt joint.(DO NOT OVERLAP!)

- Knead the ends together to finish sealant ring

- Remove protective release paper from the sealant ring

- Assemble the joint. Align structure section as straight as possible for proper entry of the tongue into the receiving groove and home the structure section. When the structure section is correctly joined, and a compression pressure obtained, PRO-STIK and EZ STIK butyl sealants will flow into a solid-pack and uniformly fill the annular space between the tongue and groove