We provide innovative railroad fasteners and a full-line of track work equipment for transit and Class 1 systems. Press-Seal Corporation strives to be the highest quality supplier to the rail and transit authorities in North America.

Our rail technology in transit, tunnel, freight and precast customers are designed to be fully comprehensive and individually focused. Listening to our customers optimizes the performance of our parts and gives stronger synergy to the relationships we develop.

Customers rely on Press-Seal for design intent and application assistance to provide a near perfect solution to an otherwise challenging problem. It’s this unique cooperation that brings customers back to Press-Seal time and again.

Railroad Production Capabilities

We focus on products that fit into the wheelhouse of our production capabilities when it comes to rubber, plastic or high-precision tooling. Our state-of-the-art facility in northeast Indiana has knowledge and experience in

- Rubber extrusion

- Rubber molding

- Thermoplastic molding

With the ability to mold or extrude materials such as isoprene, EPDM, nitrile or neoprene, we find that our rubber product solutions for railroad ties have become a unique product line that can save and/or extend the life of railroad infrastructure.

The main function of railroad tie pads are to reduce the fatigue and cracking of the concrete. This is believed to be caused by vibration and impact of passing trains.

Our thermoplastic molding capabilities can cover a diverse set of needs for many different markets. And we have decades of experience in the processes of this type of manufacturing. In particular, we design and fabricate tens of thousands of our Insulguard railroad fasteners for a variety of companies around the country.

The Insulguard fastener product line is an economical and easy to use system offering many benefits such as:

- Superior electrical insulation

- Elimination of stray current

- No galvanic corrosion of fastening system

- Excellent long-term tensile strength

Through years of experience, technology advances and engineering knowledge, Press-Seal Corporation can provide all of your inserts, bolts, adhesives and core drilling machines.

Concrete Anchoring Products

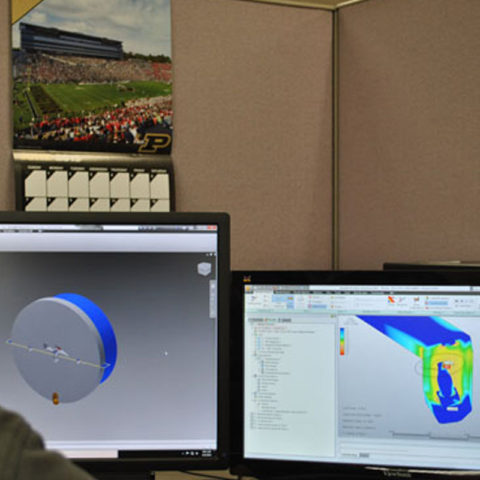

Engineering & Design

We can deliver projects of any scope and budget from concept design through to prototype production and fabrication.

With experience in mechanical, electrical and chemical engineering, we have assembled a unique skill set that is ready to take on any challenge.

- Engineering detail 2D drafting

- 3D scanning integration

- Workflows and time studies

- Data capture

- Prototype manufacture and testing

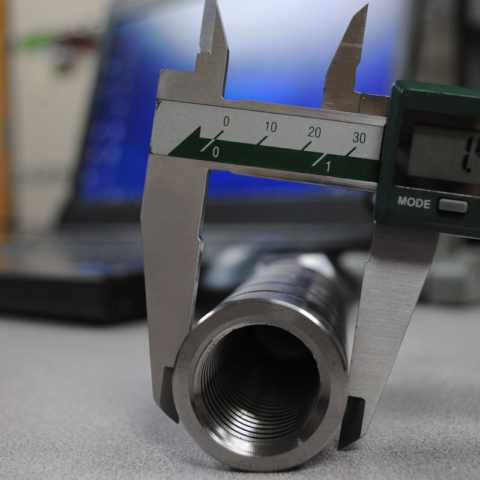

Quality Control & Testing

Laboratory proven and field tested, our products performance standards are an essential part of our commitment to providing you the highest quality products possible.

Our lab isn’t considered an expense but rather an integral part of the process we use to add value to you, our customer.

Mold Manufacturing

We utilize the latest machining equipment to produce precision parts for your anchoring needs.

Production is handled in our state-of-the-art CNC tool and die shop, while all of our machinery is produced in our fabrication department.

Polymer products are molded in-house on computer controlled injection molding machines.